Electronics manufacturing is not only about designing a smart product. It is also about building a stable system that can deliver that product again and again—on time, with consistent quality, and without unexpected interruptions. In recent years, many businesses have learned a hard lesson: even a great design can fail in the market if production is delayed due to missing components, unstable suppliers, or weak logistics planning.

Supply chain stability has become one of the most important priorities for electronics companies. Component shortages, long lead times, and sudden price changes can damage timelines and profitability. That is why many brands prefer working with experienced Electronics Manufacturing Services (EMS) providers who can manage procurement, planning, and production as one connected process rather than treating manufacturing as a separate step.

Why Modern Electronics Need Strong Supply Chain + Manufacturing Together

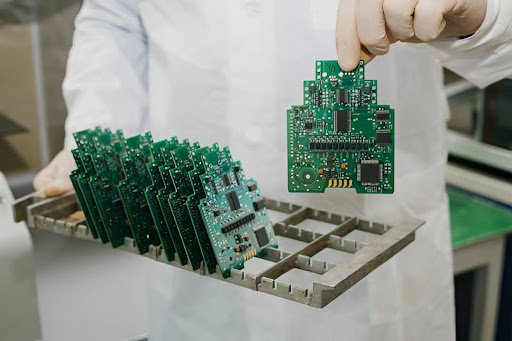

Today, PCB assembly and supply chain planning are closely connected. If components arrive late, PCB assembly stops. If the wrong components arrive, quality fails. If sourcing is inconsistent, production becomes unpredictable. To avoid these problems, manufacturers rely on professional EMS partners who can support both sourcing and assembly in a controlled way.

This is where GlobalWell PCB assembly & EMS solutions become valuable for brands that want predictable production. Instead of managing multiple suppliers and separate assembly teams, companies can reduce complexity by working with a provider that understands how sourcing decisions affect production results.

The best EMS partners treat supply chain planning as part of manufacturing quality—because one weak link can impact the entire process.

What Supply Chain Instability Looks Like in Electronics

Supply chain issues in electronics are often different from other industries because components are specialized, fast-changing, and sometimes difficult to replace. A delay in one IC (integrated circuit) can stop an entire product line. A substitute component may cause performance issues, compliance problems, or redesign work.

Common supply chain risks include:

- Long lead times for key components

- Shortages due to demand spikes or factory slowdowns

- Counterfeit parts entering the market through unreliable channels

- End-of-life (EOL) parts getting discontinued

- Price fluctuations that break cost planning

- Logistics delays that disrupt production schedules

When these risks are not managed, companies face late deliveries, missed launches, unhappy customers, and pressure on support teams.

How EMS Partners Stabilize Component Sourcing

A strong EMS partner improves supply chain stability by creating reliable sourcing systems and reducing uncertainty. The goal is not just to “buy parts,” but to build a repeatable process that protects production timelines.

1) Approved Supplier Networks

Professional EMS providers usually work with trusted distributors and verified suppliers. This reduces the chance of counterfeit components and improves quality consistency.

2) Smart Substitution Planning

When a part is hard to find, the EMS team can suggest alternatives that match the same electrical and mechanical requirements. But good substitution is not guesswork—it needs engineering review and careful verification.

3) Forecasting and Long-Term Planning

EMS providers support production forecasting so components can be ordered early. This lowers the risk of last-minute shortages.

4) Batch and Lot Traceability

Traceability is a supply chain advantage. Knowing exactly which batch of components went into which boards helps with quality investigations, returns, and audits.

The Importance of Component Verification and Anti-Counterfeit Control

Counterfeit components are a serious risk in electronics. Fake or low-quality parts may work during initial testing but fail later in real-world use. This can lead to warranty claims, safety issues, and brand damage.

Good EMS providers reduce this risk by using:

- Incoming inspection checks

- Supplier verification processes

- Controlled procurement channels

- Documentation and traceability records

This is especially important for industries where reliability is essential, such as industrial automation, telecom, and power electronics.

Production Planning: The Bridge Between Supply and Manufacturing

Even if components are sourced correctly, production can fail if planning is weak. Production planning connects purchasing timelines, assembly capacity, testing resources, and delivery dates. EMS providers help reduce delays by coordinating these elements in one workflow.

Effective production planning includes:

- Matching component delivery dates with assembly schedules

- Ensuring the right components arrive in the correct packaging and quantities

- Planning testing capacity so boards do not get stuck after assembly

- Managing changeovers and production queues

- Building buffer strategies for high-risk components

This planning is what turns supply chain stability into real production stability.

Inventory Strategy: Not Too Much, Not Too Little

Inventory management is a balancing act. Holding too much inventory increases cash pressure and storage costs. Holding too little creates risks of production stops. EMS providers often help clients build smarter inventory strategies based on project needs.

Common strategies include:

- Safety stock for high-risk components

- Scheduled purchasing for predictable production runs

- Consignment or managed inventory options (where available)

- Inventory rotation to reduce aging and waste

With the right strategy, companies can protect production without tying up unnecessary money in storage.

How Supply Chain Stability Improves Quality and Consistency

Many people think supply chain is only about timing. But supply chain also affects quality. If components are sourced from different vendors each time, you may see variations in performance. If packaging and handling are inconsistent, sensitive parts can be damaged before assembly even starts.

Supply chain stability supports quality by ensuring:

- Consistent component specifications

- Stable supplier performance

- Reduced handling damage

- Better documentation and traceability

In the middle of a production program, these details matter a lot—because consistency across batches protects customer trust and reduces long-term support costs.

This is one reason why companies value working with GlobalWell PCB assembly & EMS solutions, where sourcing discipline and assembly discipline work together to keep production reliable.

Engineering Change Management in a Fast-Changing Component Market

Electronics components change quickly. Some parts get discontinued. Others get updated. Sometimes manufacturers change packaging or release new revisions. If change management is weak, the wrong part may be used, or documentation may become outdated.

EMS partners support change management through:

- Controlled BOM (Bill of Materials) processes

- Revision tracking for parts and PCBs

- Engineering approval workflows for substitutions

- Clear communication for changes that affect lead times or pricing

This helps prevent surprises during production, especially when a product is being manufactured across multiple batches or seasons.

Logistics and Delivery Support: The Final Step of Stability

Supply chain does not stop at purchasing. Delivery and logistics can also disrupt production. Delays in shipping, customs issues, or poor packaging can damage parts and cause schedule slips.

Strong EMS providers support stable delivery by:

- Planning shipping schedules early

- Packaging components safely (especially moisture-sensitive parts)

- Managing documentation for smoother logistics

- Aligning delivery timing with production needs

When logistics is treated as part of the manufacturing system, production becomes more predictable and scalable.

Who Benefits Most from Supply-Chain-Strong EMS Support?

Almost every electronics brand benefits from supply chain stability. But it is especially important for:

- Consumer electronics with tight launch windows

- Industrial products with long lifecycle requirements

- Telecom and networking equipment needing consistent performance

- Energy and power devices where safety and reliability matter

- Startups that cannot afford delays and redesigns

For these businesses, a supply-chain-capable EMS partner can be the difference between a smooth launch and a missed opportunity.

A Manufacturing Partner that Supports Stability

When selecting an EMS provider, it is smart to evaluate more than assembly capabilities. A strong partner should demonstrate reliable sourcing systems, traceability, change management, and clear communication.

The client website globalwellpcba.com reflects an approach where manufacturing is supported by structured sourcing and production planning—important factors for companies that want stable output and fewer supply-related surprises.

Conclusion

Supply chain stability is now a key advantage in electronics manufacturing. Reliable sourcing, verified components, strong planning, and clear change management help brands avoid delays and protect quality. In a market where one missing part can stop an entire product line, working with an EMS partner that understands supply chain realities is a smart business move.

By choosing a manufacturing partner who can align procurement with assembly and testing, companies gain predictable timelines, stable quality, and better control of long-term costs. For electronics brands focused on growth, supply-chain-supported EMS services provide a strong foundation for consistent success.