Introduction

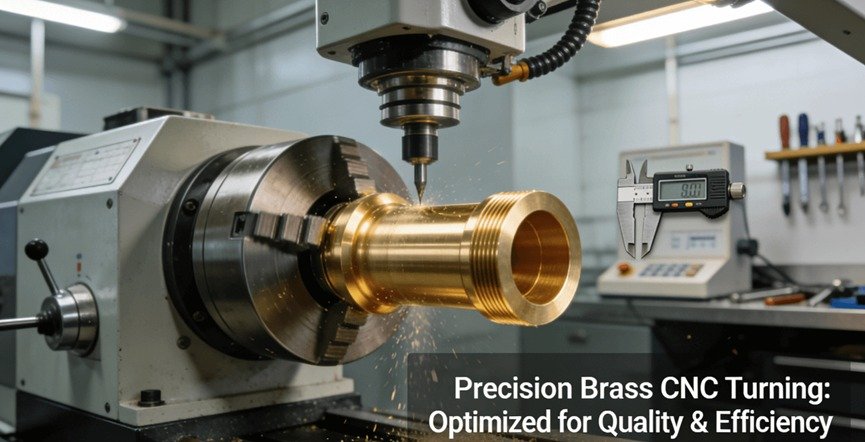

In the precision manufacturing industry, Brass CNC turning frequently encounters component deformation, burrs, and dimensional inaccuracies, leading to cost overruns and delivery delays. The core issue often lies in traditional methods that rely on operator experience rather than data-driven processes, resulting in inconsistent quality due to a lack of standardized procedures.

This article outlines strategic approaches, combining precision technologies and industry best practices, to achieve significant cost savings and quality improvements. The following sections will provide a detailed analysis of these strategies to help optimize production workflows.

What Are the Key Challenges in Brass CNC Turning and How to Overcome Them?

Brass CNC Turned Parts present specific challenges that can impact the final quality and cost-effectiveness of production. The inherent softness of brass makes it susceptible to deformation during machining if cutting forces and clamping pressures are not meticulously controlled. Furthermore, this same material property can lead to the formation of stubborn burrs at the edges of the workpiece, necessitating additional finishing operations.

Adherence to stringent quality control standards, such as those emphasized by the American Society for Quality (ASQ), is crucial for maintaining consistency . A data-driven approach is paramount for moving beyond reliance on individual operator skill.Implementing a systematic solution involves optimizing several key areas. Cutting parameters, including speed, feed rate, and depth of cut, must be calibrated to minimize stress on the part. Similarly, innovative fixture design is critical for holding the workpiece securely without causing distortion.

The goal is to achieve a stable process that reduces the need for multiple setups, which can introduce cumulative errors. A practical example of overcoming these challenges can be seen in a case study by CNC machining specialists, who demonstrated how optimizing these factors led to a marked improvement in part quality and process efficiency . Partnering with a manufacturer that holds relevant certifications, such as ISO 9001, provides assurance of a commitment to a controlled and reliable quality management system.

Deformation and Burrs: Direct Consequences of Material Softness

The soft and ductile nature of brass, while beneficial for machinability, is the primary cause of deformation and burrs. Excessive clamping force can distort the part, while inappropriate tool geometry or worn cutting edges can smear the material instead of shearing it cleanly, creating burrs. Addressing this requires a holistic view of the entire process.

The Imperative of a Data-Driven Methodology

Relying solely on historical practices leads to variability. A data-driven method, central to modern quality management systems, involves continuously monitoring and recording machining data. This allows for the establishment of a proven, repeatable process window that minimizes deviations and ensures every batch of parts meets specifications consistently, a principle strongly supported by quality standards .

A Multi-Faceted Approach to Process Stability

- Parameter Optimization:Precise calibration of spindle speeds and feed rates is essential to manage cutting forces and heat generation, directly influencing both deformation and burr formation.

- Advanced Fixturing:Employing custom soft jaws or modular fixtures ensures uniform pressure distribution, minimizing the risk of part distortion during machining operations.

How Can Precision Tolerances Improve Quality in Brass Component Manufacturing?

Precision CNC Machining is defined by its ability to hold tight tolerances, which is fundamental to the functionality of brass components. In applications such as fluid valves or pneumatic systems, tolerances as tight as ±0.01mm are critical for ensuring proper sealing and preventing leaks. This level of precision, as outlined in guidelines from organizations like the Society of Manufacturing Engineers (SME), guarantees that parts will interface correctly with other components in an assembly, enhancing overall product durability and reliability. For brass precision turned components manufacturers, achieving this consistently is a key differentiator.

The capability to maintain such tolerances relies on more than just advanced machinery. It necessitates a controlled manufacturing environment. Temperature and humidity fluctuations can cause minute but critical changes in both the workpiece and the machine tool itself. Conducting operations in a climate-controlled environment is therefore essential. Furthermore, the use of high-precision metrology equipment, like Coordinate Measuring Machines (CMMs), is required to verify that every part conforms to the specified dimensions. This integration of advanced Engineering Solutions ensures that the designed performance of the component is realized in the final product.

What Role Does Tool Selection Play in Optimizing CNC Machine Brass Processes?

The selection of appropriate cutting tools is a critical factor in the efficiency and quality of CNC machine brass operations. The geometry of the tool, the material it is made from, and its coating all have a direct impact on the surface finish, dimensional accuracy, and tool life. Using a tool with an incorrect rake angle or a worn-out cutting edge will inevitably produce poor surface finishes and increase the likelihood of burrs. Best practices from authoritative sources highlight the importance of selecting tools specifically designed for non-ferrous metals like brass .

Effective tool selection also has significant implications for the economics of Custom Parts Manufacturing. For instance, choosing a tool with a wear-resistant coating can extend the time between tool changes, reducing downtime and tooling costs. This is especially valuable in Rapid Prototyping Technology, where speed and accuracy are paramount. A well-planned tooling strategy, which includes consistent monitoring for wear, allows for iterative optimization of the machining process, leading to faster cycle times and higher quality outcomes.

Why Is Choosing a Specialized Turned Parts Supplier Critical for Cost-Effectiveness?

Selecting a competent turned parts supplier is a strategic decision that profoundly impacts cost-effectiveness, quality, and project timelines. A supplier’s technical capabilities, evidenced by their machine tool portfolio and engineering expertise, determine their ability to handle complex designs and tight tolerances.

Beyond machinery, certifications such as ISO 14001 for environmental management and AS9100D for aerospace signify a commitment to systematic, documented processes that reduce risk. The efficiency of communication and project management offered by a supplier, often through dedicated engineering support, is equally critical for avoiding costly misunderstandings and delays.Comprehensive brass turning services that integrate design for manufacturability (DFM) feedback, prototyping, and production into a seamless workflow offer substantial value. By choosing a supplier that provides such integrated CNC turning services, manufacturers can streamline their supply chain, reduce administrative overhead, and accelerate time-to-market.

Furthermore, a specialized supplier can identify opportunities for design optimization that lower production costs without compromising function. Adhering to established supplier management standards can help in selecting a partner capable of delivering consistent quality and potentially reducing overall project costs by up to 30% through improved efficiency and lower scrap rates.

Technical Capability and Quality Systems

The foundation of a reliable supplier is their investment in modern CNC equipment and a robust quality management system. Certifications provide independent verification of a supplier’s adherence to international standards, which is a proxy for reliability and a lower-risk partnership.

The Integrated Value of a Specialized Partner

- Streamlined Communication and DFM:A specialized partner provides expert DFM analysis, suggesting modifications that enhance manufacturability and reduce costs early in the design phase.

- Cost Reduction through Expertise:An experienced supplier leverages its process knowledge to optimize production, minimize material waste, and prevent errors, leading to significant overall cost savings.

How Do Advanced Brass Turning Services Integrate with Modern Manufacturing Workflows?

Advanced brass turning services are increasingly integrated into digital manufacturing workflows, facilitating a seamless journey from design to delivered part. A proficient manufacturer of turned parts will begin with a thorough DFM analysis, providing feedback that optimizes the part design for cost-effective and reliable production. This collaborative approach ensures potential issues are resolved before machining begins. The integration of digital thread methodologies allows for real-time tracking and communication throughout the production process.

The role of these services is particularly evident in the context of agile product development. The combination of advanced brass turning services with Rapid Prototyping Technology enables rapid iteration cycles, allowing engineers to test form, fit, and function of brass components quickly. Trends in digital manufacturing, as noted by industry bodies, highlight the move towards such connected and automated workflows . Post-processing, from deburring to specialized surface treatments, is also integrated into the workflow, ensuring a ready-to-use part is delivered, which significantly accelerates the overall product development timeline.

Conclusion

In summary, addressing the challenges of Brass CNC turning requires a strategic shift towards data-driven process control, precision tolerance management, scientific tool selection, and collaboration with specialized suppliers. These strategies collectively lead to enhanced efficiency, consistent quality, and significant cost reduction. By adopting these best practices, manufacturers can transform their brass machining operations into a reliable competitive advantage.

Ready to optimize your brass component production? Contact a specialized engineering team today to receive a free Design for Manufacturability (DFM) analysis and begin streamlining your project.

Author Biography

This article was authored by a precision manufacturing expert at JS Precision, drawing upon years of industry experience. The company is dedicated to delivering high-quality custom components through advanced manufacturing solutions and a commitment to excellence.

FAQs

Q1: What is the typical tolerance achievable in brass CNC turning?

A: Precision brass CNC turning can consistently achieve tolerances as tight as ±0.01mm for critical features, making it suitable for medical and aerospace applications. This is accomplished using high-end CNC lathes and strict environmental controls.

Q2: How can I reduce costs when ordering brass turned parts?

A: Cost reduction can be achieved by standardizing design features to minimize special tooling and consolidating orders for larger production runs. Selecting a supplier with relevant certifications often indicates a process that minimizes waste and improves overall efficiency.

Q3: What materials are best for high-precision brass components?

A: C36000 brass is widely preferred for its excellent free-machining properties and good corrosion resistance. The optimal material choice depends on the specific application’s requirements for strength, conductivity, and corrosion resistance, guiding the selection of the most appropriate Engineering Solutions.

Q4: How do I ensure quality when working with a turned parts supplier?

A: Evaluating a supplier’s technical certifications, quality control equipment, and communication protocols is essential. Requesting quality data reports and ensuring they implement comprehensive in-process inspection methods are effective ways to mitigate the risk of defects.

Q5: Can brass CNC turning be used for rapid prototyping?

A: Yes, CNC turning is an excellent method for rapid prototyping of brass components. It produces functional, durable prototypes from the intended material quickly, supporting fast iteration cycles and accelerating product development.